Ford’s Secret Sport Sedan: Aluminum Sable SHO’s Brief Reign

Benjamin Hunting | Dec 31, 2025

The automotive landscape of today is a tapestry woven from materials and methodologies that, just a few decades ago, were considered the exclusive domain of aerospace or high-end racing. Advanced alloys, intricate composites, weight-saving carbon fiber, and ultra-strong adhesives now underpin the construction of our everyday vehicles. This widespread adoption didn’t happen overnight; the 1990s stand out as a pivotal decade, marking the initial, tentative steps away from steel as the undisputed monarch of automotive construction. It was a period when technological capabilities finally began to align with the ambitious visions of engineers and designers, eager to push the boundaries of vehicle performance and efficiency.

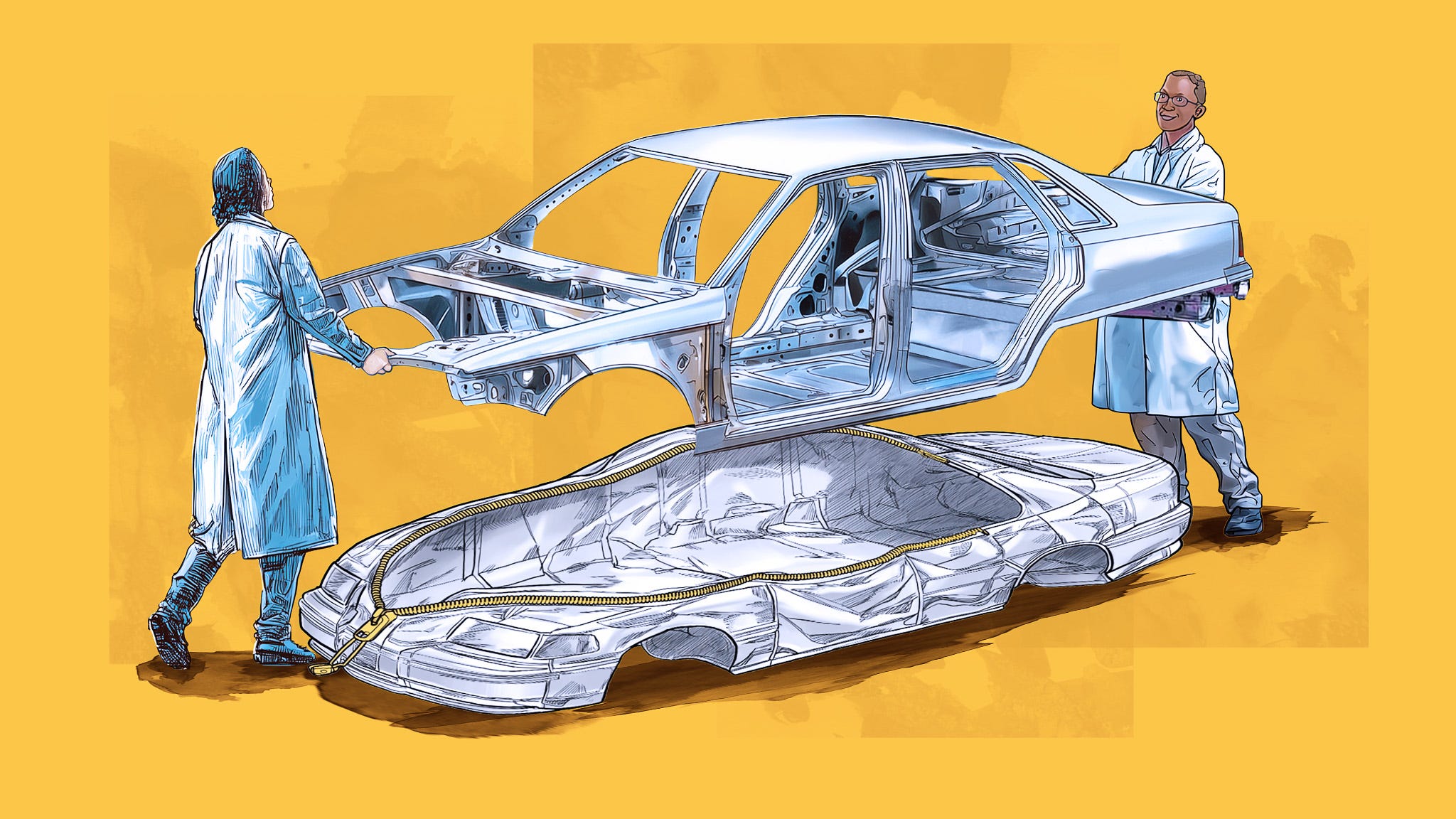

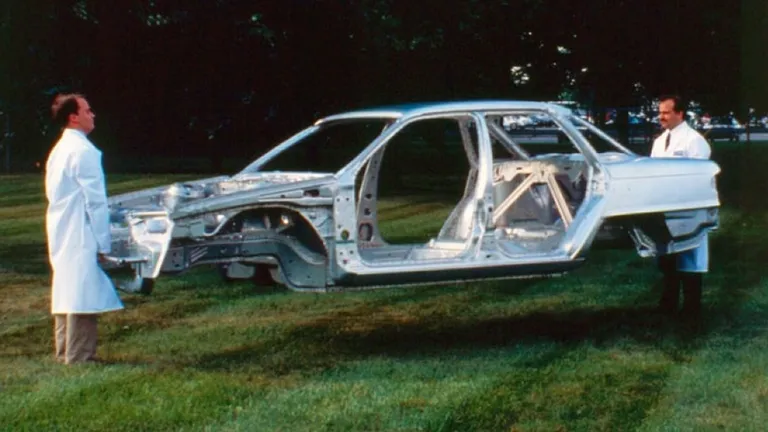

Large corporations, by their very nature, are often slow to pivot from deeply ingrained production habits. This makes it all the more remarkable to learn that Ford, a company that garnered significant attention in 2015 for its audacious shift to primarily aluminum body panels for its best-selling F-Series pickup, had actually initiated its foundational research into this lightweight metal nearly a quarter-century earlier. This pioneering spirit gave birth to a project that would briefly tantalize automotive enthusiasts and showcase Ford’s engineering prowess: the Aluminum Intensive Vehicle, affectionately known as the Super Sable.

This is the untold story of Ford’s secret sport sedan, the Mercury Sable SHO that went far beyond its production counterpart, making an ultra-light splash in the world of experimental vehicles. Known officially as the Aluminum Intensive Vehicle (AIV), this project was far more ambitious than it needed to be, creating a tantalizing “what if?” scenario for automotive history. It presented a timeline where Ford could have positioned itself at the absolute forefront of performance and lightweight technology, had it chosen to bring this radical dream car you’ll regret owning to mass production. Instead, it remained an exclusive, almost mythical creation, largely unknown to all but the most dedicated fans of the departed Mercury brand and advanced automotive engineering.

The Genesis of a Lightweight Dream: Aluminum Futures, Steel Budgets

The fundamental allure of lightweight alloys like aluminum has always been their significant weight savings compared to the traditional heavyweights of steel and iron. This potential for reduced mass quickly caught the attention of the automotive industry, which found early applications for aluminum in specialized components. However, the idea of an entire vehicle structure crafted from aluminum was a far more complex undertaking, fraught with engineering challenges and economic considerations.

In the late 1980s and early 1990s, as fuel efficiency regulations tightened and performance demands increased, automotive engineers began to seriously explore alternative materials. Ford, recognizing the strategic importance of this shift, launched its Aluminum Intensive Vehicle program. The goal was audacious: to create a production-viable vehicle with a significant portion of its structure and body panels made from aluminum. The Mercury Sable, a stylish and aerodynamically advanced sedan already known for its modern design, was chosen as the platform for this ambitious experiment. Its existing architecture provided a solid foundation, while its “upscale” Mercury branding offered a potential avenue for introducing advanced, premium technologies to the market.

Why the Mercury Sable SHO?

The Mercury Sable SHO (Super High Output) was not just any Sable; it was the performance pinnacle of the lineup, equipped with a potent Yamaha-designed V6 engine. This choice for the AIV program was strategic. A high-performance variant would inherently benefit more from weight reduction, translating directly into improved acceleration, braking, and handling dynamics. Furthermore, associating the advanced aluminum technology with a performance model could help justify the increased costs associated with new materials and manufacturing processes, potentially appealing to a niche market willing to pay a premium for cutting-edge engineering. This decision underscored Ford’s intent to use the AIV not just as a materials testbed, but as a demonstrator for future performance capabilities.

The AIV project wasn’t merely about swapping steel for aluminum; it involved a holistic re-engineering of the vehicle. This included developing new joining techniques, such as advanced adhesives and specialized rivets, as traditional welding methods for aluminum are vastly different and more complex than for steel. The entire manufacturing process had to be rethought, from stamping and forming to assembly and painting, pushing the boundaries of what was considered feasible in mass production at the time. This deep dive into material science and manufacturing innovation was a costly endeavor, but one that Ford believed was essential for its long-term competitiveness.

Engineering Marvel: The Aluminum Intensive Vehicle

The heart of the Aluminum Intensive Vehicle program was its innovative construction. Ford didn’t just replace steel panels with aluminum; they designed a complex space frame structure using extruded aluminum sections, coupled with stamped aluminum body panels. This approach maximized rigidity while minimizing weight, a holy grail for automotive engineering. The result was a vehicle that weighed significantly less than its steel counterpart, promising substantial improvements in performance and fuel economy.

Key Innovations and Materials

- Aluminum Space Frame: Unlike traditional unibody construction, the AIV utilized a sophisticated aluminum space frame, providing exceptional structural integrity.

- Stamped Aluminum Panels: Exterior body panels, including the hood, trunk, fenders, and doors, were crafted from lightweight aluminum sheet.

- Advanced Joining Techniques: Given the challenges of welding aluminum, Ford employed a combination of riveting, structural adhesives, and advanced laser welding in specific areas to ensure robust and durable joints.

- Powertrain Integration: The powerful 3.0-liter Yamaha V6 engine, producing 220 horsepower, was perfectly complemented by the lighter chassis, enhancing its already impressive performance.

The impact of these material choices was profound. A standard Mercury Sable SHO of the era weighed approximately 3,400 pounds. The Aluminum Intensive Vehicle, by contrast, shed hundreds of pounds, bringing its curb weight down to a mere 2,900 pounds. This reduction of over 500 pounds was a monumental achievement for a sedan of its size, offering performance metrics that rivaled much smaller, more specialized sports cars. The lighter mass meant quicker acceleration, shorter braking distances, and more agile handling, transforming the Sable SHO into a true performance sleeper.

This commitment to pushing technological boundaries wasn’t limited to the physical structure. Ford also explored advanced manufacturing processes and quality control methods to ensure the aluminum components met the rigorous standards required for a production vehicle. This intensive research and development laid crucial groundwork for future Ford projects, demonstrating the viability of lightweight materials even if the specific application of the AIV didn’t reach mass production.

Performance and Potential: A Glimpse of What Could Have Been

With its significantly reduced weight, the Aluminum Intensive Mercury Sable SHO was a revelation on the road. The 220-horsepower Yamaha V6, already a gem in the standard SHO, truly came alive when tasked with moving a lighter chassis. Acceleration times improved, and the car felt noticeably more nimble and responsive. Contemporary reports from those who had the rare opportunity to drive these prototypes spoke of a car that transcended its humble family sedan origins, delivering a driving experience closer to European sport sedans of the time.

Imagine a family sedan that could sprint from 0 to 60 mph in under 7 seconds, offering precise steering and confident braking, all while maintaining the comfort and practicality of a four-door vehicle. This was the promise of Ford’s secret sport sedan. It wasn’t just about raw speed; it was about a harmonious balance of power and agility that set it apart. The AIV demonstrated that a mainstream automaker could produce a vehicle with truly exceptional dynamics, challenging the perception that performance cars had to be small, impractical coupes.

Comparative Analysis: AIV vs. Standard SHO

The Vanishing Act: Why Ford’s Secret Sport Sedan Didn’t See the Light of Day

Despite its undeniable engineering brilliance and impressive performance, Ford’s Aluminum Intensive Vehicle ultimately remained a prototype, a tantalizing “what if” in automotive history. Its vanishing act from the public eye was due to a confluence of factors, primarily economic and logistical, that made mass production unfeasible at the time.

Cost Prohibitions and Manufacturing Complexities

The primary hurdle was cost. Aluminum, especially in the quantities and forms required for an entire vehicle structure, was significantly more expensive than steel. The specialized manufacturing processes, including the unique joining techniques and dedicated assembly lines, also added substantial overhead. For a mainstream brand like Mercury, targeting a broad consumer base, the potential retail price of an aluminum-intensive Sable SHO would have been prohibitively high, placing it out of reach for most buyers and severely limiting its market viability. This was a common challenge for many advanced technological ventures of the era, where the promise outstripped the practical economics of scale.

Furthermore, the infrastructure for repairing aluminum vehicles was virtually non-existent in the early 1990s. Body shops were equipped for steel, and training technicians for aluminum repair would have been another massive undertaking, adding to the total cost of ownership and potential customer resistance. This highlights a critical aspect of automotive innovation: it’s not enough to build a better car; it must also be maintainable and affordable within the existing ecosystem.

Market Timing and Strategic Priorities

The market for high-performance, premium sedans was also different in the early 90s. While there was a burgeoning interest in sport sedans, the idea of paying a significant premium for lightweight construction in a Mercury Sable was a hard sell. Ford’s strategic priorities likely shifted towards more immediate, high-volume projects that could deliver quicker returns on investment. The F-Series, for instance, represented a much larger market where even incremental improvements in fuel economy and payload capacity, eventually achieved through aluminum, would have a massive impact.

The AIV program was also a learning exercise. Ford invested heavily in understanding aluminum’s properties, how to work with it, and the challenges of integrating it into a production environment. The knowledge gained from the Super Sable project was invaluable, even if the car itself never saw dealer showrooms. It was a long-term investment in future capabilities, rather than an immediate product launch.

The Enduring Legacy: From Super Sable to F-150

While Ford’s secret sport sedan, the Aluminum Intensive Mercury Sable SHO, never reached mass production, its impact on the company’s long-term strategy and technological development cannot be overstated. The project served as an invaluable crucible, forging the expertise and understanding that would eventually manifest in one of the most significant automotive shifts of the 21st century: the aluminum-bodied Ford F-150.

Paving the Way for Future Innovation

The engineers and designers who worked on the AIV project gained firsthand experience with the complexities and benefits of aluminum construction. They learned about:

- The challenges of forming and stamping aluminum panels without tearing or cracking.

- The intricacies of joining dissimilar materials and ensuring structural integrity.

- The effects of aluminum on vehicle dynamics, ride quality, and crash performance.

- The necessity of developing new manufacturing processes and training for assembly line workers.

This accumulated knowledge became a foundational pillar for Ford’s subsequent ventures into lightweight materials. Without the pioneering work on the Super Sable, the transition of the F-Series to aluminum in 2015 would have been a far riskier and more challenging undertaking. The AIV was, in essence, a large-scale, real-world laboratory that de-risked future aluminum applications.

The lessons learned also extended beyond just aluminum. The project fostered a culture of innovation and a willingness to challenge conventional wisdom within Ford’s engineering departments. It demonstrated that even seemingly insurmountable challenges related to materials and manufacturing could be overcome with persistent research and strategic investment. This mindset became crucial as the automotive industry continued to evolve, facing new demands for efficiency, safety, and performance.

It’s fascinating to consider how various industries grapple with the adoption of advanced technological trends. Just as Ford was exploring new materials, other sectors were also undergoing significant transformations. For instance, the discussion around the future of display technology, like 8K, reflects a similar pattern of innovation hitting practical and economic barriers before finding its niche or evolving. Similarly, the advent of AI-powered innovations across industries, from automotive design to even skincare, shows a universal push for efficiency and personalization through technology, often starting with ambitious, experimental projects like the AIV.

The “What If” Scenario: Impact on Detroit and Beyond

The story of Ford’s secret sport sedan compels us to ponder the “what if” scenarios. What if the economic conditions had been different? What if manufacturing costs for aluminum had plummeted sooner? If the Aluminum Intensive Mercury Sable SHO had made it to mass production, it could have fundamentally altered the landscape of the American automotive industry. Ford would have been decades ahead of its competitors in mainstream aluminum vehicle production, potentially forcing other Detroit automakers to accelerate their own lightweighting programs.

A Catalyst for Change

Such a move could have:

- Accelerated Industry Adoption: A successful aluminum Sable SHO could have pressured GM and Chrysler to invest more heavily in similar technologies much earlier.

- Redefined Performance Sedans: It would have set a new benchmark for performance in a family sedan segment, emphasizing not just raw power but also agility and efficiency through lightweight design.

- Influenced Design and Engineering: The AIV’s unique construction methods might have inspired new approaches to vehicle architecture across the industry.

- Boosted Aluminum’s Profile: It would have significantly raised the public’s awareness and acceptance of aluminum as a primary automotive material, beyond just specialized components.

The AIV represented a bold vision for the future, one where performance and efficiency were not mutually exclusive but rather complementary outcomes of advanced engineering. Its existence, even in limited numbers, showcased Ford’s capacity for groundbreaking innovation and its willingness to invest in technologies that would ultimately shape the future of transportation.

The lessons learned from the AIV program underscore a critical aspect of industrial progress: not every innovation needs to be an immediate commercial success to be profoundly influential. Sometimes, the most valuable contributions come from experimental projects that push boundaries, reveal new possibilities, and lay the groundwork for future breakthroughs. The Super Sable was a quiet pioneer, a testament to the idea that true progress often happens behind the scenes, far from the glare of the showroom floor.

Conclusion: A Secret No More

The Aluminum Intensive Mercury Sable SHO, Ford’s secret sport sedan, remains a fascinating chapter in automotive history. It was a vehicle born of ambition, pushing the boundaries of material science and manufacturing at a time when such concepts were largely confined to specialized industries. While it never achieved mass production, its legacy is undeniably significant, directly influencing Ford’s later, highly successful adoption of aluminum in its F-Series trucks and other vehicles. It demonstrated Ford’s long-standing commitment to innovation and its willingness to invest in the future, even if the immediate commercial returns were not apparent.

The Super Sable was more than just a lighter version of an existing car; it was a vision of what was possible, a testament to the ingenuity of engineers who dared to challenge the status quo. Its brief reign in the experimental labs of Detroit might have been short-lived and largely unnoticed by the wider public, but its impact reverberated through the decades, culminating in a revolution in automotive construction. Today, as we see more and more lightweight materials integrated into vehicles across all segments, it’s worth remembering the quiet pioneers like Ford’s Aluminum Intensive Vehicle, the secret sport sedan that briefly ruled Detroit’s engineering dreams and then, seemingly, vanished, only to re-emerge in a different form, shaping the cars of tomorrow.